A Concept Creation with No Restrictions

In July of 2020, during the celebration of the 60th Anniversary of Grand Seiko, a novel concept movement was announced. This was the first time in Grand Seiko’s history that the brand introduced a concept creation with no plan to commercialize, but purely to showcase the achievement of a young engineer and designer from the Grand Seiko team. That gentleman was Mr. Takuma Kawauchiya, who began his career with Seiko Instruments, now Seiko Watch Corporation, in 2010. He got involved with the research and development of mechanical watches for Grand Seiko and the Shizukuishi Watch Studio, and his ultimate goal was to create the most precise watch he possibly could. Interestingly enough, he was given no restrictions in his endeavor. There was no concern for manufacturing capabilities or capacities, and no regard for what the potential cost could be. In the end, his goal was just to create the most precise watch possible.

Born in Shizukoka city, Mr. Kauwauchiya earned his Bachelor Degree from the Dept. of Industrial Engineering and Management at Tokyo Institute of Technology. His thesis was on the cockpit of the shinkansen, or bullet train, and how to increase the efficiency of the design of the dashboard’s meters. He also loves music and is a proficient guitar player. After earning his degree, he decided to pursue a career as a professional musician playing guitar across Japan and Europe for several years.

Ultimately, Mr. Kawauchiya decided to pursue another career path in watchmaking, which lead him to WOSTEP (Watchmakers of Switzerland Training and Educational Program). After a challenging two years, he graduated from watchmaking school and found his way to Seiko Instruments.

Mr. Kawauchiya has led an incredibly interesting life, and while it may be ironic, his careers seem to have all influenced his unique creation, the T0 Constant Force Tourbillon. A constant force mechanism has been incorporated into movements with a tourbillon before. However, the approach from Mr. Kawauchiya was unique. By integrating the two, keeping the mechanism as close to the balance as possible, it improves the efficiency of energy delivery. This integration of having the constant force and tourbillon as one unit revolving around the same axis was a unique concept and a world’s first. Mr. Kawauchiya should be very proud.

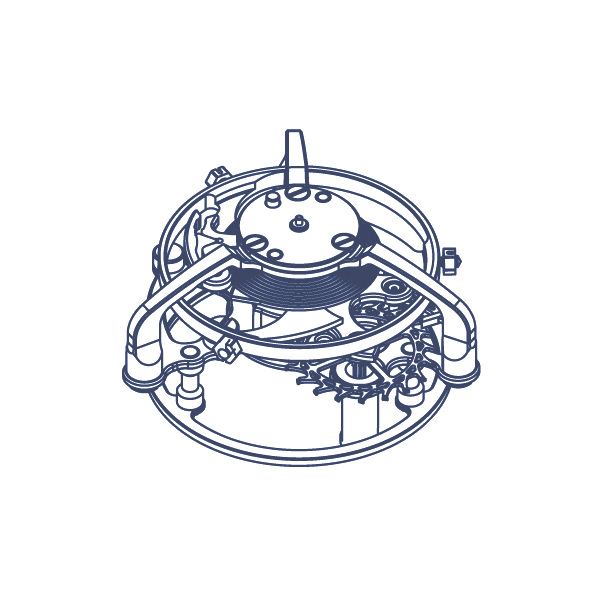

Early prototype of the T0.

First, he created a block sample consisting of the heart of the movement, two-layered carriages and the minimum gear trains needed to test his idea. He used as many available parts from current watches because he couldn’t wait to try it out! The concept proved effective, and development continued.

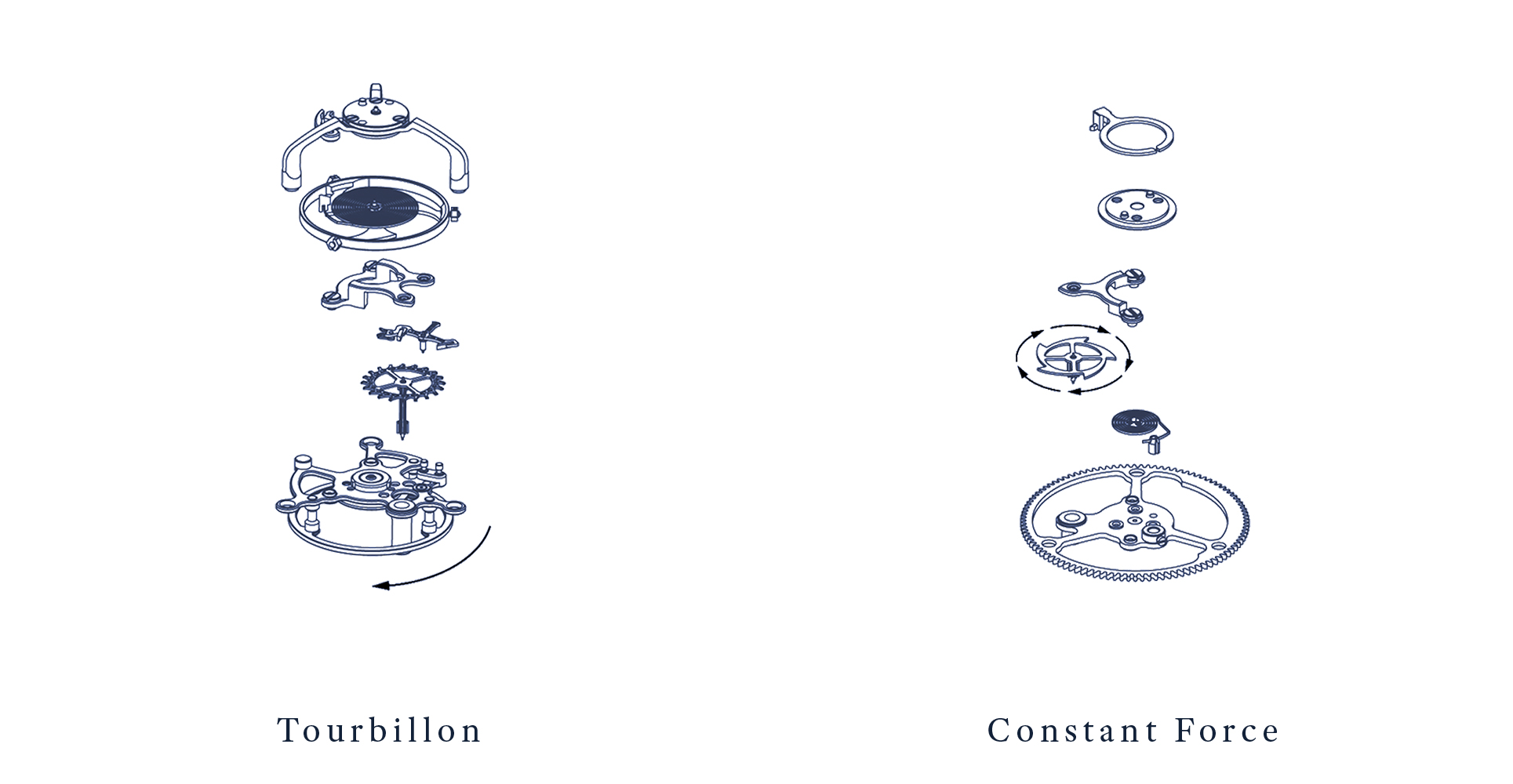

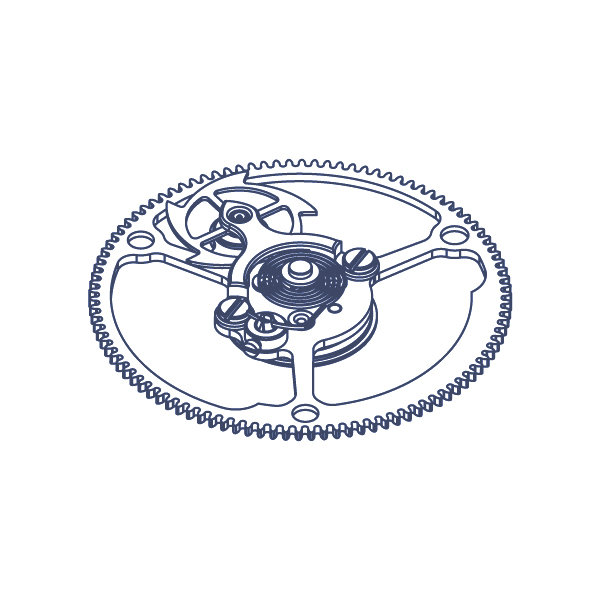

The two mechanisms integrated in one unit.

In order to create the highest precision possible, he had to analyze the largest issues with performance in a movement. The accuracy of a watch can greatly vary depending on how much power is left in the watch. A full wind has the most power. This moment is known in watchmaking as T = torque, and 0 = zero hours have passed since it was fully wound. For example, T24 would mean that 24 hours have passed since the watch was fully wound. When the watch is at T0, it has the greatest potential for high accuracy. As its power dwindles, it loses that potential. Mr. Kawauchiya knew that a constant force mechanism was the solution to this problem.

Another large issue and why the performance of a watch can vary greatly depends on position, especially from horizontal to vertical positions. This is where the tourbillon comes in. A tourbillon rotates the escapement and balance around a fixed wheel so that the load from gravity is being evenly distributed to all sides of the balance wheel and its staff. A tourbillon was developed for pocket watches that constantly sit in one position, but it can have benefits for a wristwatch by helping to keep the performance consistent even in varying positions. While many tourbillons on the market today are more ornamental and few are documented of having higher accuracy or performance traits, such as being submitted to COSC for certification, the tourbillon does have merit for better performance.

The T0 focuses on efficiency. By utilizing both of these mechanisms together as one integrated unit, efficiency can be increased and a highly stable rate can be achieved. This is how T0, while being only one concept movement, achieved an astounding rate of ± 0.5 seconds per day during its two-week wear test, by compensating for varying torque and position and doing it as efficiently as possible!

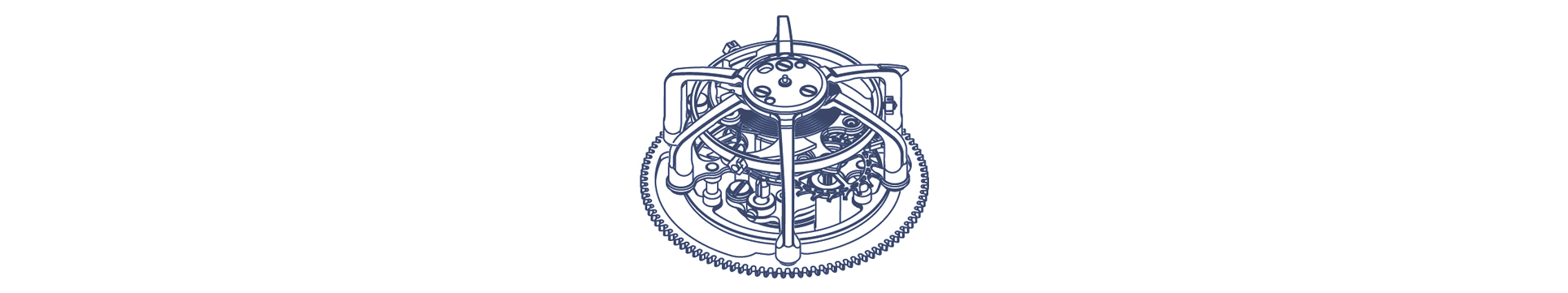

As you might imagine, utilizing both of these mechanisms, with two carriages rotating around the same fixed wheel could be quite a lot of weight and have impact on performance. This is why Mr. Kawauchiya chose to utilize titanium for the two sets of carriage arms, which are treated blue by anodic oxidation. The use of titanium reduces the weight substantially and is about the only trait that this movement has in common with the Credor Fugaku Caliber 6830.

This movement is actually based on the Grand Seiko caliber 9S65 (though you would never guess it), has a hacking mechanism (a rare trait in tourbillons), a 72 power reserve with indicator, two barrels with a parallel layout (a first for the brand or in Seiko in general), 340 components and the highest frequency ever used in a movement with a constant force mechanism, 28,800 vibrations per hour!

Aside from all the facts already mentioned, the balance is free-sprung, a trait only shared with our 9SA5 caliber in Grand Seiko, though using nuts instead of screws. The amplitude is virtually constant during its first 50 hours of operation and the vertical position error is incredibly minuscule. The finishing is done completely by hand, of which Mr. Kawauchiya did a good portion with his own hands. The movement features pearling, beveling and the Shizukuishi River Finish as seen in the new 9SA5 caliber. It took over 3 months just for finishing! This, to say the least, is quite an impressive caliber.

How does it work?

Mr. Kawauchiya: Once energy is transferred from the barrels through the gear train, it reaches the large external wheel of the outer carriage that carries the constant-force mechanism. The constant force stop wheel and escape wheel turn around the same stationary wheel.

As the outer carriage turns, it charges the constant force spring connecting the outer and inner carriage and the charged energy will drive the inner tourbillon carriage. A pallet stone “stopper” attached to the inner carriage, which meshes with the teeth of the stop wheel, is used to control the distribution of energy from the constant force spring, and as the energy of the constant-force spring is released, the energy is supplied to the inner carriage that drives the escape wheel that meshes with the stationary wheel. The escape wheel now supplies constant and uniform energy to the balance.

While the inner carriage is rotating, the outer carriage is stopped by the engagement of the stopper and the stop wheel. When the inner carriage rotates by 6 degrees, the engagement of the stopper and the stop wheel is released and the outer carriage rotates to provide energy to the constant force spring. When the outer carriage rotates by 6 degrees, the next tooth of the stop wheel engages the stopper and the outer carriage stops again. This sequence of movements takes place in 1-second cycles, so that the second hand makes deadbeat motion.

What inspired the design for T0?

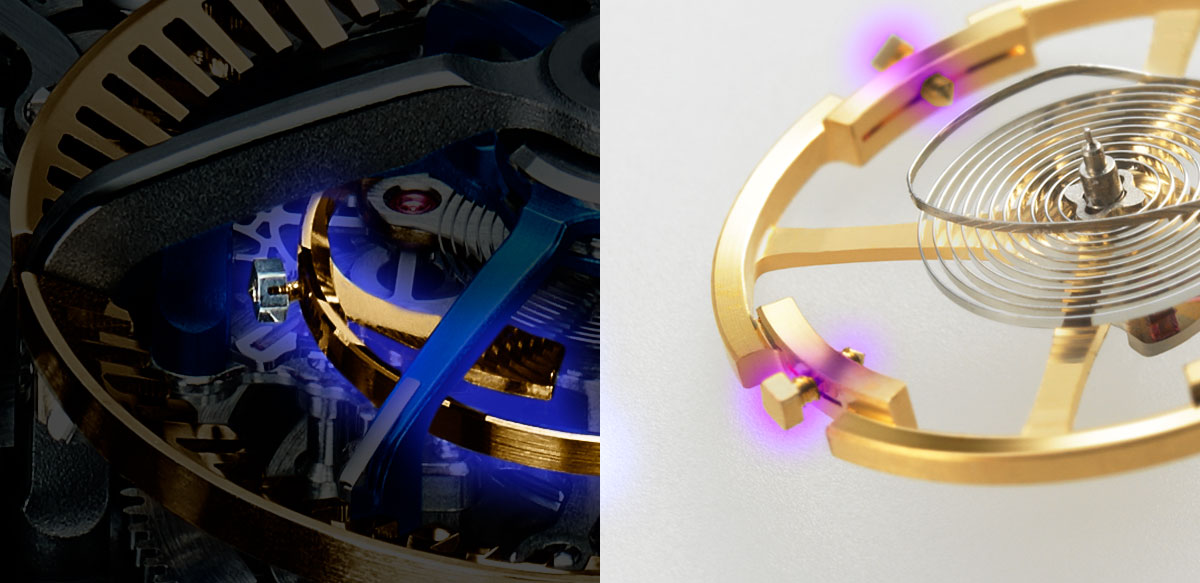

The heartbeat, or kodō, for T0, the constant force tourbillon.

Mr. Kawauchiya: I’m always attracted to the motions of mechanical watches, and I tried to maximize the beauty and the dynamic movement of the parts. One of the most attractive points of T0 is its two carriages that beat like a heart, so I made this part stand out so that people can enjoy its Kodo, or heartbeat. Also, I made the wheel train’s motion more visible by skeletonizing the bridges and making some wheels bigger. It is enjoyable to see when setting the time and winding up the crown.

The Shizuku finish of T0 mirrors the effect of water drops creating ripples at the center of the constant force tourbillon mechanism.

Mr. Kawauchiya (continued): In terms of finishing, it is inspired by water drops, or Shizuku in Japanese, from the melted snow in Shizukuishi and ripples. Just like the ripples caused by water drops that fall on the water surfaces, I wish to share through T0 the world of Grand Seiko to watch lovers throughout the world. That is why I applied onto the main plate the Shizukuishi River Finish in a rippled pattern so that it starts from the carriages, which is the heart of the movement.

Why is the jewel for the carriages blue?

The blue jewel located at the center of the heart of the movement

Mr. Kawauchiya: There are two reasons. One is T0’s design theme of water drops and ripples, which reminds me of the blue color. Also, I used the blue color only in the jewels for carriages to make them stand out from the whole movement. I believe blue is the most appropriate color to celebrate Grand Seiko’s 60th anniversary.

Is the anglage/beveling done by hand?

Beveling of the bridges executed by hand

Mr. Kawauchiya: Yes, all the rims of the main plate and bridges are polished by hand. Also, the iron parts including the ratchet wheel as well as all of the pivot end surfaces are hand polished. I did some of the processes myself and it took tremendous time.

Can you further explain how the T0 is a world first?

Mr. Kawauchiya: It is the first mechanism to integrate constant-force mechanism and tourbillon as one unit on the same axis. By doing so, as the constant-force is placed close to the balance, torque can be transferred from the constant-force to tourbillon with minimum loss and change, and it also can spare space horizontally. It is also the world’s first 8 beat, the highest VPH movement with a constant-force mechanism.

How does the constant force mechanism disengage after 50 hours?

Mr. Kawauchiya: During the first 50 hours, the outer constant-force carriage jumps by 6 degrees per second to wind up the constant-force spring. After about 50 hours, as the torque from the mainspring becomes not enough to wind up the constant-force spring completely, the degree of jumping motion decreases from 6 to 5 to 4…and the amplitude decreases as well. When about 60 hours passes, the outer carriage stops moving by itself and the two carriages will move together, functioning only as a tourbillon.

Why did you choose ceramic for the stop wheel?

Mr. Kawauchiya: A constant-force stores the force of a mainspring and releases it in constant intervals. Thus, as a key component, a stop wheel is required to have high durability and low friction resistance because this part bears high torque from the two barrels. I applied a precise ceramic gear for the stop wheel, whose processing was precise to a micron level. As a result, T0 can operate with certainty every second without the wear of the stop wheel.

Is there an overcoil in T0?

Mr. Kawauchiya: No. The main reason is to not increase the depth of the movement. The two-carriage construction inevitably leads to a certain depth and I didn’t want to make it any thicker.

Do you think you would ever be able to reduce the size of T0?

Width 36.3mm x Height 8.22mm (6.09mm without tourbillon)

I think it is possible. T0’s carriage already takes a relatively small space horizontally by integrating the two mechanisms into a unit, and I think the movement diameter can be further reduced.

Why did you choose timing nuts instead of screws like 9SA5?

T0’s regulating nut with slit (left) and 9SA5’s meantime screws (right)

Mr. Kawauchiya: Meantime screws like those in 9SA5 are widely used and are suitable for large scale production, but I wanted to use the regulating nut type in T0 because it is more rare and unique, and also believed that it would be able to control the torque by adding slits into the regulating nut. I was aware it wouldn’t be easy but I took the challenge. Please also take a look at the slit on the tiny regulating nuts when looking at T0’s picture.

Can you explain the reason for the design of the screws on the bridges of T0?

The unique screws highlighted on the T0

Mr. Kawauchiya: T0’s screw with 6 grooves is inspired by its unique 6-armed carriage. Function wise, it has the merit to tighten the screw firmly without slipping, by using a specially designed driver. The stable feeling when tightening this screw is pretty addictive!

What are some ways T0 and the new 9SA5 are influenced by each other?

Mr. Kawauchiya: T0 affected 9SA5 with the use of twin barrels, free-sprung balance, and some of its finishing.

9SA5, on the other hand, affected T0 with the Shizukuishi River Finish.

Fujieda-san, the designer of 9SA5, and I constantly discussed what is an ideal watch during the development processes of both calibers. I got a lot of advice from Fujieda-san on T0’s development as well. We call them ‘’brother calibers.’’

Does the introduction of the T0 concept mean Grand Seiko will now focus more on high complications?

Mr. Kawauchiya: We wouldn’t say so. T0’s complication is a result of aiming to create an ultra-high precision mechanical movement, not to create a complicated mechanism. However, I personally think there is no reason to not make another complication if it is based on Grand Seiko’s philosophy.

What kind of music did you play as a musician?

Mr. Kawauchiya: This is an interesting question. As a guitarist, I played all kinds of genres. At first, I was mainly playing Jazz fusion, and afterward, I expanded into Rock, Pop, and Classical music. It was wonderful experience that I played at José Cura’s opera in his Japanese performance and Sónar, a music festival held annually in Barcelona.

Lastly, do you think this movement will ever go into production?

Mr. Kawauchiya: As we just revealed this new concept creation, we do not have any plans for now. But, as the movement designer, I personally hope that day will come soon.

We would like to sincerely thank Mr. Kawauchiya for his time and congratulate him on his development!

To learn more, please visit hs-ny.org to see the lecture at Horological Society of New York given by Brand Curator Joseph Kirk, with guests Mr. Akio Naito and Mr. Takuma Kawauchiya. Grand Seiko is a proud sponsor and supporter of the Horological Society of New York.